Unveiling the Art and Science of Heat Treatment: Enhancing Metal Performance.

In the world of metallurgy, where strength, durability, and performance are paramount, heat treatment stands as a cornerstone process. From the towering structures of skyscrapers to the intricate components of aerospace machinery, heat treatment plays a vital role in shaping the materials that power our modern world. In this blog, we'll delve into the fascinating world of heat treatment, exploring its principles, processes, and profound impact on metal performance.

Understanding the Basics:

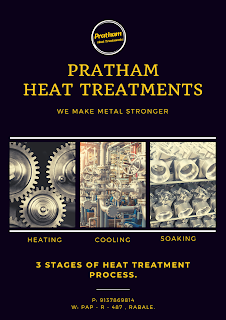

At its core, heat treatment is a controlled process of heating and cooling metals to alter their physical and mechanical properties. By subjecting metals to carefully orchestrated thermal cycles, metallurgists can tailor their microstructure, hardness, strength, and other characteristics to meet specific requirements for diverse applications.

The Journey Through Heat Treatment:

The journey through heat treatment begins with meticulous preparation of the metal workpiece, followed by heating to precise temperatures in specialized furnaces. During heating, atoms within the metal lattice undergo rearrangement, leading to changes in grain structure, phase composition, and mechanical properties.

Quenching, the rapid cooling stage of heat treatment, introduces a dramatic transformation as the heated metal is plunged into quenching mediums such as oil, water, or air. This rapid cooling locks in the desired microstructure, creating hardened surfaces and internal stresses.

But the journey doesn't end there. Tempering, a crucial post-quenching step, involves reheating the hardened metal to temper its extreme hardness and brittleness. This process imparts toughness and ductility, striking a delicate balance between strength and resilience.

Applications Across Industries:

The applications of heat treatment span across a myriad of industries, each harnessing its transformative power to elevate performance and reliability. In the automotive sector, heat-treated engine components withstand the rigors of combustion, while aerospace manufacturers rely on heat-treated alloys to defy the forces of gravity.

In the realm of tooling and machining, heat-treated cutting tools slice through steel with precision, while bearings and gears in industrial machinery endure relentless cycles of stress and strain. Even in the medical field, orthopedic implants benefit from heat treatment's ability to optimize biocompatibility and corrosion resistance.

Embracing Innovation and Excellence:

As technology advances and materials evolve, so too does the art and science of heat treatment. From advanced simulation techniques to novel alloy compositions, metallurgists continue to push the boundaries of what's possible, unlocking new realms of performance and efficiency.

Yet, amidst the cutting-edge innovation, one thing remains constant: the unwavering commitment to quality and excellence. Whether it's a towering skyscraper or a microscopic medical device, the success of every application hinges on the precision and expertise of those who wield the power of heat treatment.

Comments

Post a Comment