Hardening Plant

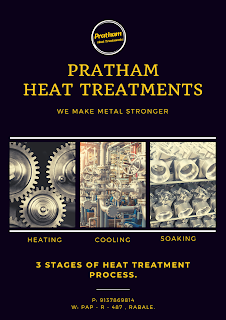

Guide to a Metal Hardening Plant The industrial world relies on strong, dependable metals. But how do these metals achieve their impressive strength and durability? The answer often lies in a fascinating process called metal hardening. Today, we’ll take you on a virtual tour of a metal hardening plant, exploring the magic behind this crucial treatment. The Heart of the Plant: The Furnace The workhorse of any metal hardening plant is the furnace. Here, precisely controlled heat plays a starring role. Metals are meticulously heated to specific temperatures based on their composition and desired outcome. This heating alters the internal microstructure of the metal, making it more susceptible to the next step: quenching. The Quench: Transformation Takes Shape Once heated, the metal is rapidly quenched, typically in water, oil, or a specialized solution. This rapid cooling “traps” the altered microstructure, locking in the desired properties like hardness and strength. The q...